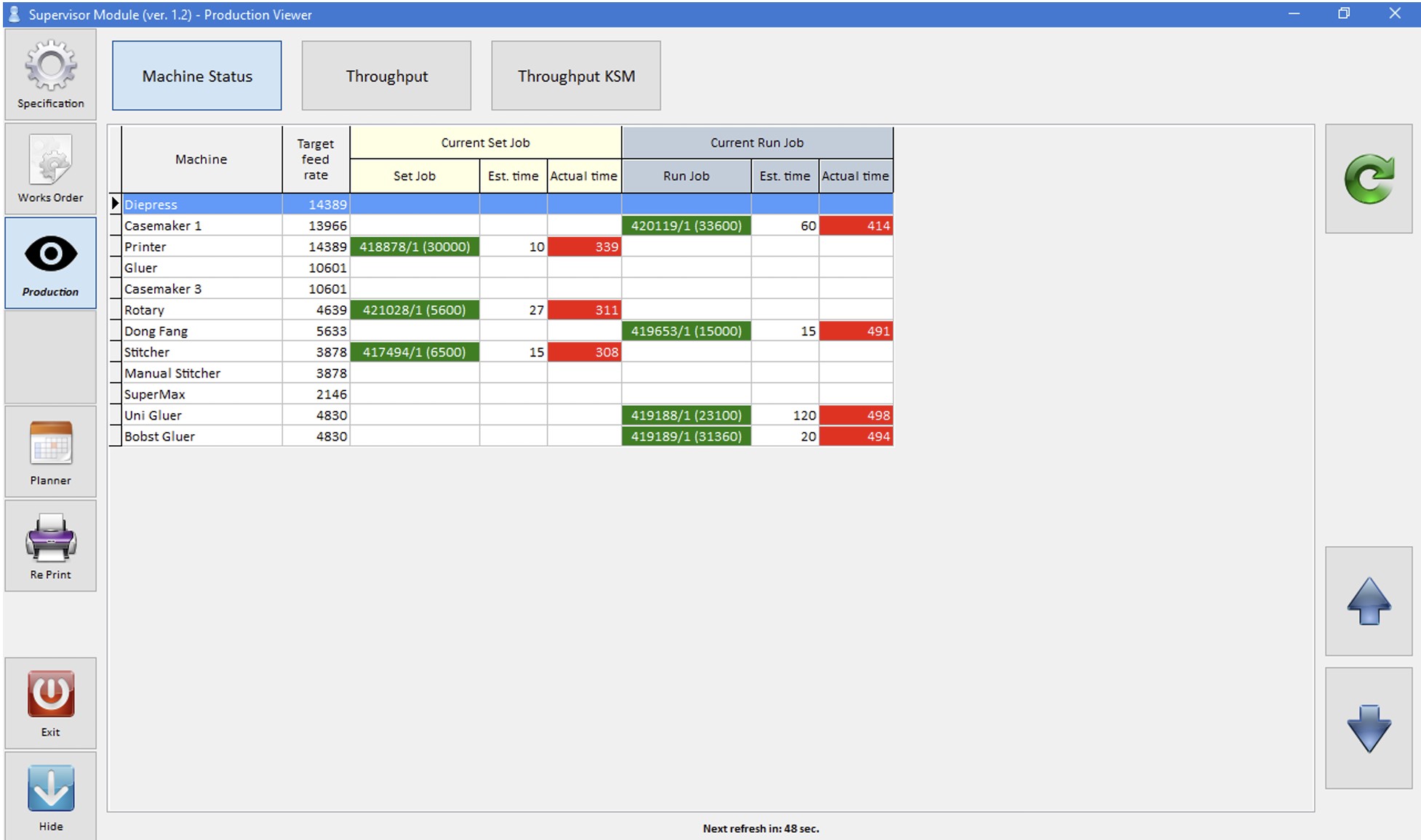

Picture the scene: You’ve installed Shop Floor Data Collection—now, every machine in the factory is visible at the touch of a button. You can instantly spot deviations from the plan and take action to keep production on track.

You notice an issue with the casemaker… what do you do?

You call the floor supervisor, but he’s busy managing the engineers servicing the platen—on the other side of the factory, or maybe even in a different building! He’s completely unaware of the problem because he’s not receiving real-time updates from SPOCS. That makes him the weak link in the information chain.

Not anymore!

With the Supervisor Module, running on a tablet, the Production Supervisor has live factory insights at their fingertips—anytime, anywhere. No delays. No guesswork. Just real-time visibility and immediate action to keep operations running smoothly.

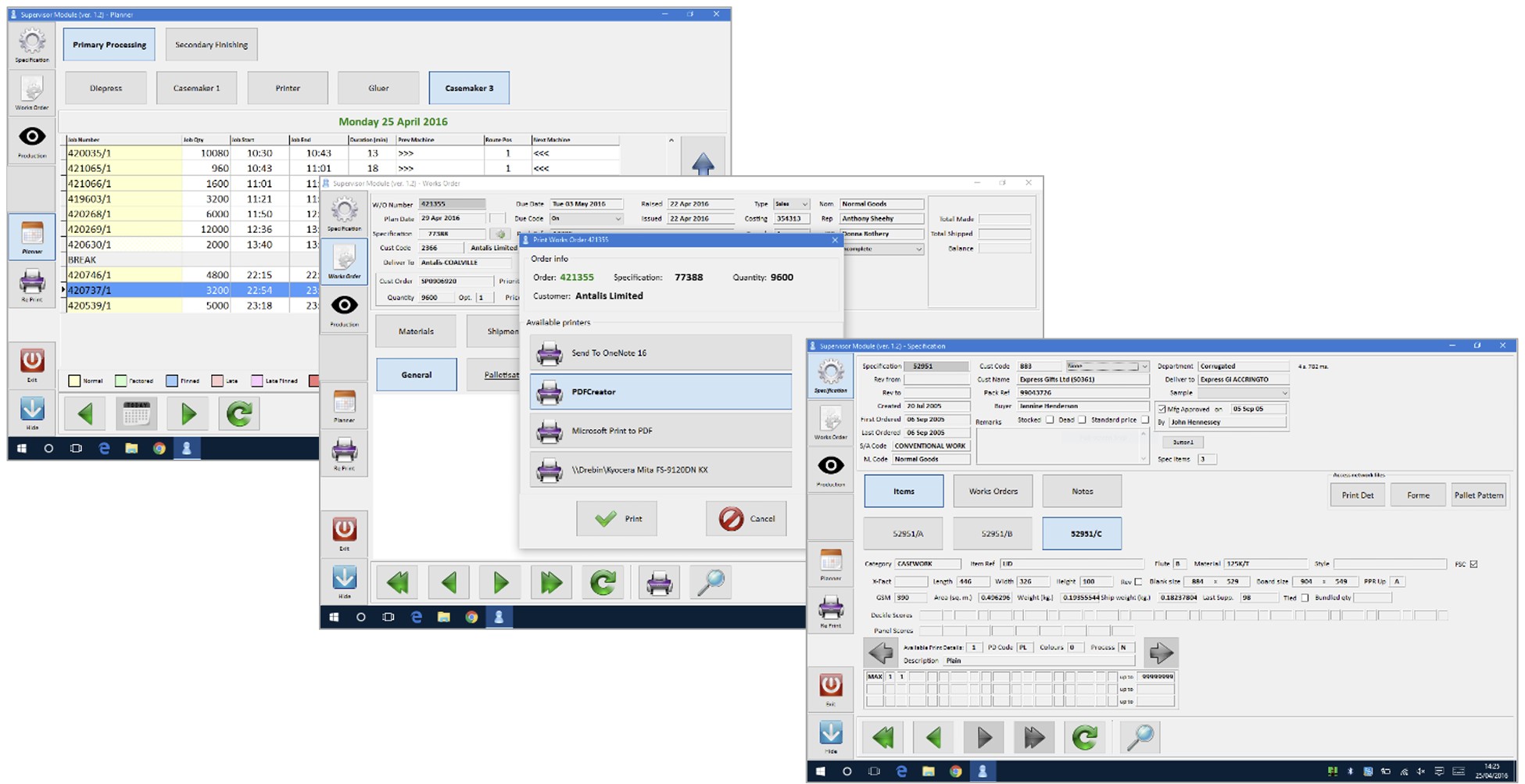

With the Supervisor Module, the Production Supervisor gains real-time visibility of factory operations. Tabs display the planner, SFDC operations, spec, and works order screens, ensuring they are always fully informed about the status of any job in progress.

This module eliminates countless calls to and from the office, freeing the supervisor to spend more time on the floor, where they’re needed most.