When margins are tight and you’re already purchasing as efficiently as possible, the key to improving profitability lies in efficiency. Having complete visibility of your factory—knowing exactly where everything is, analysing machine performance, and scrutinising waste—allows you to run operations more effectively, reduce costs, and enhance customer service.

When margins are tight and you’re already purchasing as efficiently as possible, the key to improving profitability lies in efficiency. Having complete visibility of your factory—knowing exactly where everything is, analysing machine performance, and scrutinising waste—allows you to run operations more effectively, reduce costs, and enhance customer service.

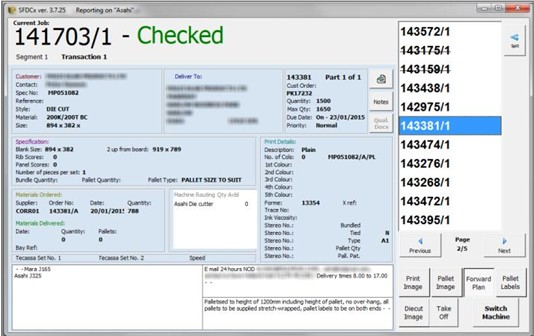

Our Shopfloor Data Collection system delivers this in real time, using touchscreens and barcode readers to provide instant insights—eliminating the need for additional production clerks.

Benefits of the SFDCx System

- Job Visibility & Efficiency: Operators can see the full list of queued jobs for their machine, allowing them to prepare in advance. This also prevents unnecessary slowdowns caused by uncertainty about upcoming work.

- Real-Time Data Processing: The touchscreen interface reads and writes directly to the database, continuously creating and updating Production Segments and routing records. This ensures that results are instantly available, significantly reducing time spent resolving misinformation.

- Access to Essential Drawings: Operators can view print, die-cut, and palletisation drawings directly at the machine, improving accuracy and reducing errors.

Production Oversight

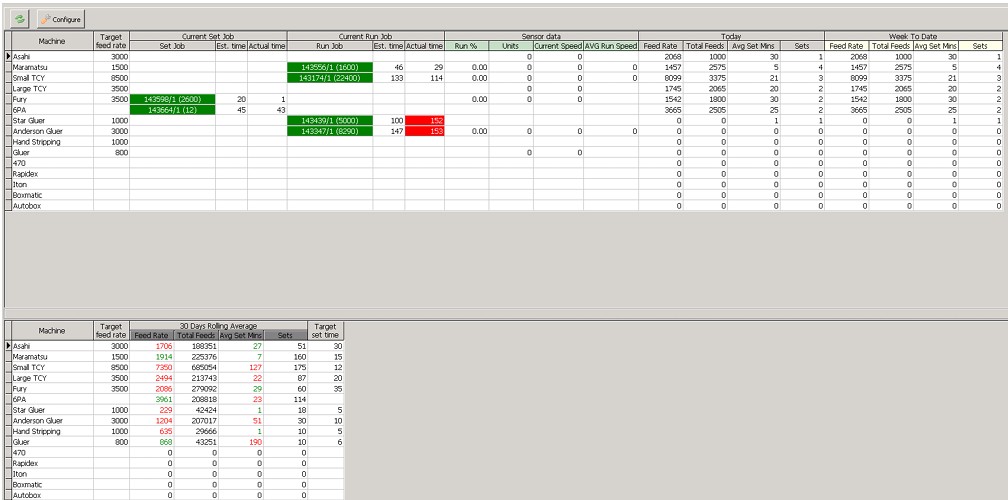

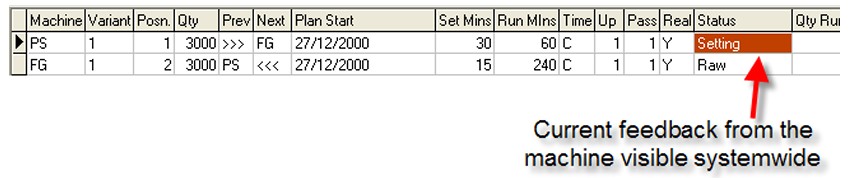

The Production Viewer provides managers with real-time visibility into each machine's performance—allowing quick identification and resolution of issues.

Meanwhile, back in the office, anyone with access to the Routing Editor can instantly check the status of any job—whether it’s in progress or already completed.

The SFDCx system integrates seamlessly with the S32Plan planning system, ensuring that completed jobs are automatically updated in the plan as soon as SFDCx reports them finished. Additionally, performance data captured by SFDCx is used to refine future job estimates—allowing set and run times to improve based on past performance.

Quality Checks

The application enables comprehensive quality checks, allowing operators to log detailed inspections with optional photos and notes.

For users with BRC certification, the system ensures full compliance by recording ink batches, viscosity checks, and all other quality control measures associated with a job.

Supervisor checks and design approval further ensure that job quality is meticulously controlled throughout the process.

All logged checks are instantly accessible on the main system through our powerful reporting tools, providing complete traceability and quality assurance.