If you're managing multiple machines, customers with shifting priorities, and urgent orders, this is the solution you need.

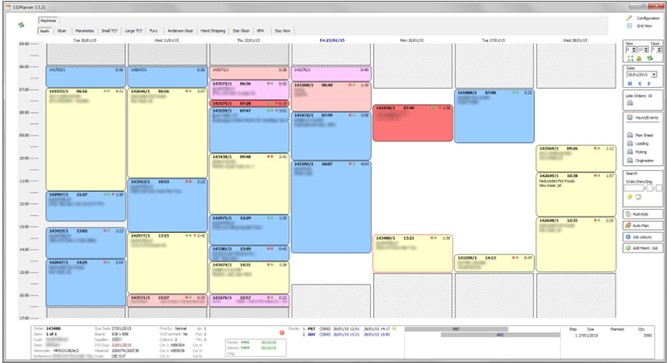

SPOCS incorporates live, real-time capacity planning. Orders entered are instantly reflected on the plan. If the requested due date isn't feasible, the sales administrator is immediately notified as they enter the order. Once the order is on the plan, you get a clear, graphical visualisation, with the ability to easily rearrange work using drag-and-drop. If moving a rush job forward causes delays to others, they turn red, alerting you to the potential impact of the change.

What you do is visible on any SPOCS station (or even on a wall screen), reducing the time spent managing calls from sales and streamlining your production process.

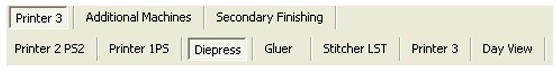

S32Plan uses data from your main SPOCS32 system and updates in real time whenever changes are made (e.g., new orders, board booked in). There's no need for secondary data entry, spreadsheets, or hand-written planning sheets—S32Plan handles it all. Designed for use by your Planner on a large screen, it enables efficient planning for all machines, providing a week-at-a-glance view with no limits on forward planning.

Each block represents a works order item on the machine, with the size of the block reflecting the job's duration. The grids are organised into sections, designed to meet the planning needs of even the largest sheet plants.

Each grid can be customised by the user to display work across one or more machines. Jobs can also be flagged for special attention in various ways. When a job is highlighted, its details appear at the bottom of the screen, allowing for informed decisions on combining work sequences to minimise washdown and blade changes.

Jobs can be pinned or edited by right-clicking on their block in the grid. This functionality also allows you to move jobs between machines. When a job is moved to a different machine, the system checks the machine limits before allowing the transfer, ensuring that the move is feasible.

Late again?

Any job that becomes late will turn pink, and the late jobs counter will increase. This provides instant feedback on the impact of inserting rush jobs and helps track the achievement of production targets.

Moving Around

Moving jobs on the plan is as simple as dragging the job to the desired position. When you move a job on one machine, it will also shift on subsequent machines. For instance, you won’t be able to place it on the Gluer until it’s slotted. If you decide to slot it a day later, it will also adjust on the Gluer.

While the large screen view is excellent for organising work, there comes a time when you need to present that information in meetings or share it with the floor. S32Plan can do both, offering an A3 printout that shows the full spread of work, along with individual running/picking lists for machines.

Live Update

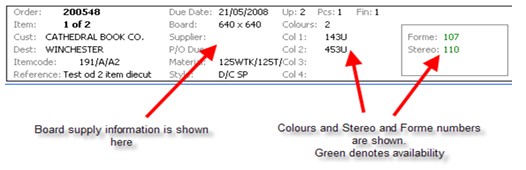

Changes made in the main system update S32Plan in real time. New orders entered will instantly appear on the grid. The “traffic light” on each block shows the availability of board, formes, and stereos, and the grid will update once these items are booked in.

Capacity Planning

The planner itself is a powerful tool, but what about when new jobs are entered? This is where SPOCS32 truly shines. With S32Plan active, when new orders are entered, SPOCS32 immediately notifies the operator if the required due date is achievable. If not, it provides an alternative date for when the job can be scheduled. Jobs that require special treatment can still be "walked through" as usual. This ensures that new work enters the plan smoothly, and sales staff are kept informed about production build-ups in real time. The system even balances capacity across functionally equivalent machines to optimise efficiency.

Working Hours

The system stores standard working hours for each machine, but these can be adjusted for specific events, such as overtime or machine maintenance.