Stock control is a crucial aspect of running a smooth and efficient sheet plant. This SPOCS module is designed to make maintaining accurate stock records quick, easy, and cost-effective.

PalletScan 2, a mobile application, operates on a tablet paired with a handheld scanner. It seamlessly tracks finished stock from creation to despatch, ensuring stock levels and values remain accurate at all times. With PalletScan 2, stock quantities are always correct, stock values are always correct, and every pallet is traceable.

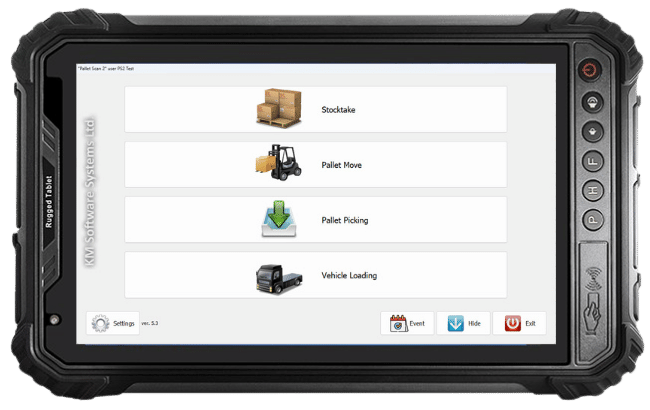

The application can run in four modes: Stock Take, Pallet Move, Pallet Picking, and Vehicle Loading, providing complete flexibility for efficient stock management.

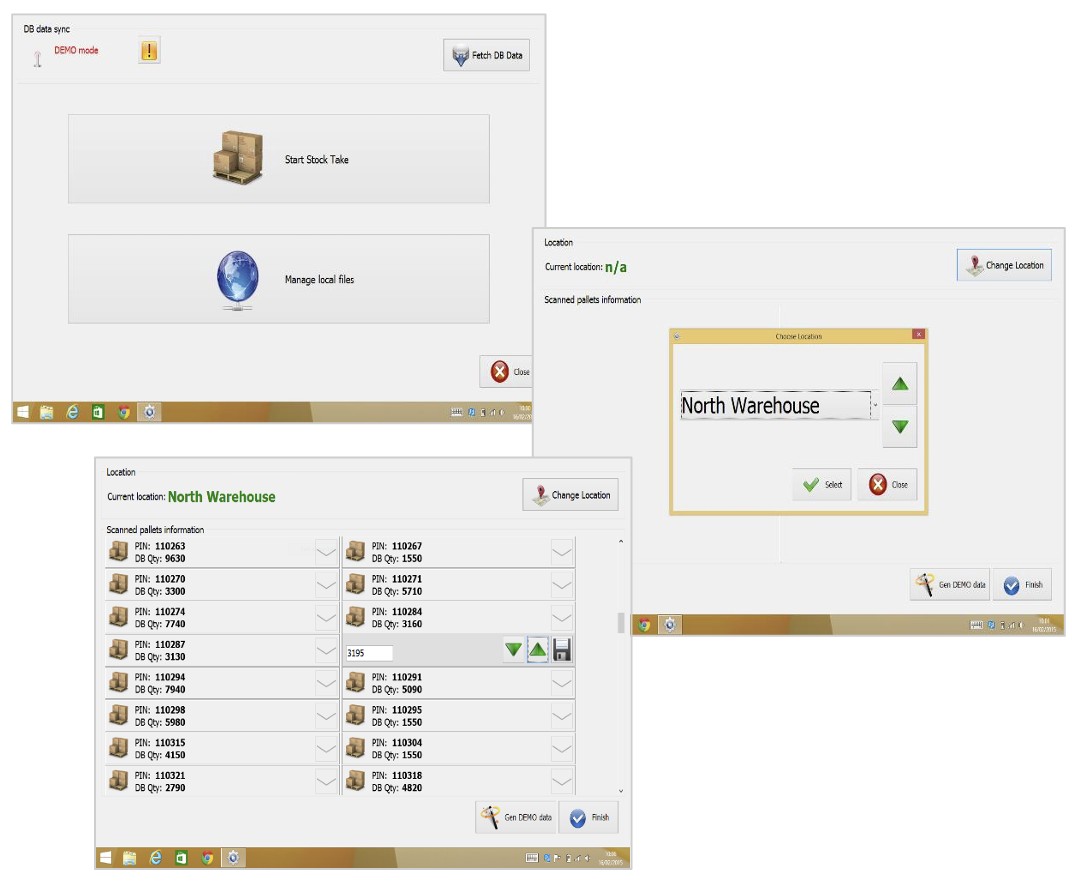

Stock Take

This feature of PalletScan 2 allows you to quickly verify your stock, including actual pallets, quantities, and locations, and reconcile the data with your SPOCS system.

The process begins by downloading stock data from your system to the tablet. As you move through your stock, you’ll scan the location barcode followed by each pallet’s PIN barcode. This instantly checks whether each pallet is in the correct location and has the expected quantity according to system records.

If discrepancies arise, you can update the location (much easier than moving the pallet!) and/or adjust the recorded quantity. Once the stock take is complete, the revised data is uploaded back to the system, ensuring your stock records are accurate and up to date. Additionally, any unusual discrepancies will be flagged for further investigation.

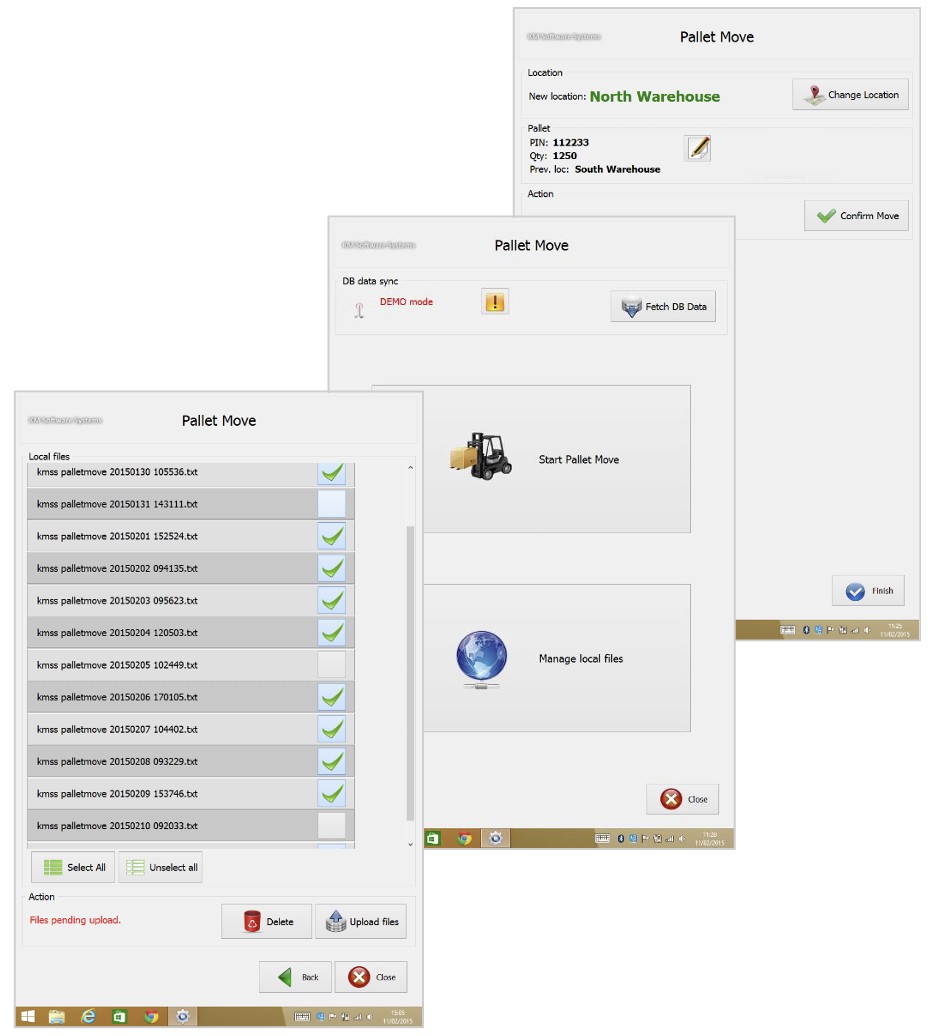

Pallet Move

This mode allows you to record any changes in pallet location quickly and accurately. Simply scan the location barcode, followed by the pallet’s PIN barcode. The system will display the current recorded location of the pallet, allowing you to confirm or update its location and quantity as needed.

This ensures stock records remain precise, minimising errors and improving overall inventory management.

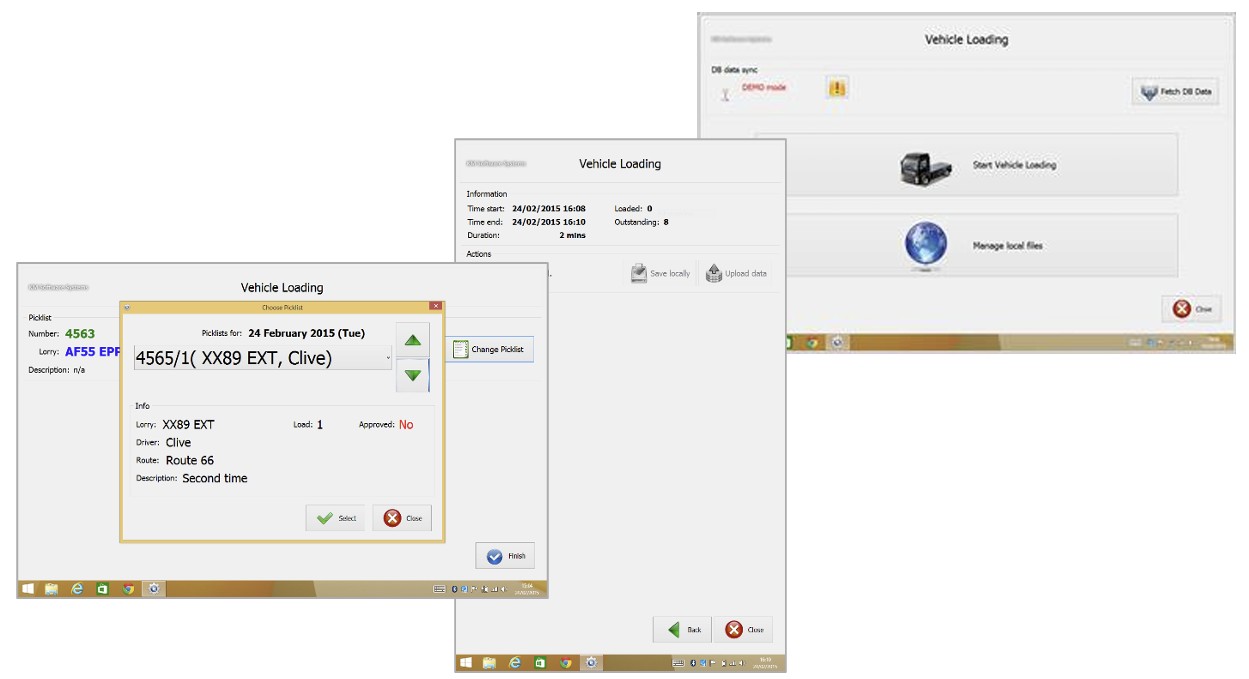

Vehicle Loading / Pallet Picking

This feature makes it easy to track pallets as they are moved to the picking location or loaded onto a vehicle.

Start by downloading the day’s picklists. Select the first picklist, then scan each pallet’s PIN barcode as it is moved to the picking location or loaded onto the vehicle. Once all the pallets are loaded for an order, the order is removed from the screen, providing a clear view of the remaining tasks.

Once all pallets for a picklist are processed, you can move on to the next picklist and vehicle.

If adjustments are needed, the "Unload" option allows for quick corrections. Scan the pallet’s PIN barcode, and if it has already been marked as loaded, tap "Unload" to return it to the picklist.

This ensures an accurate, efficient, and flexible stock movement process.